High volumes, high standards

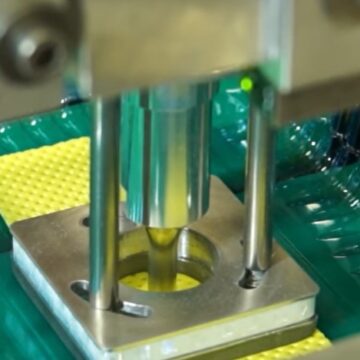

Our ultrasound technology is the most flexible, clean and repeatable way to meet different packaging needs for both cutting and welding.

Depending on the sector and requirements, we develop automatic or manual solutions that guarantee the highest level of productivity at high cycles and absolutely airtight and safe sealing. In addition, our ultrasonic systems allow you to monitor all welding parameters via software, eliminating errors, deviations and problems of any kind.

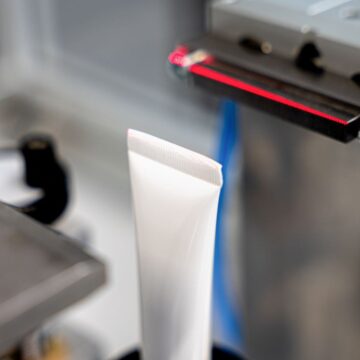

In particular, our solutions for food & beverage and cosmetics do not alter the content at all and are validated by leading brands with very high hygienic, aesthetic and production standards.

The Sonomax team is on hand to assist you at every stage of the process, from the prototype stages of the project through development to production.

Contact us to explain your needs!

You can weld

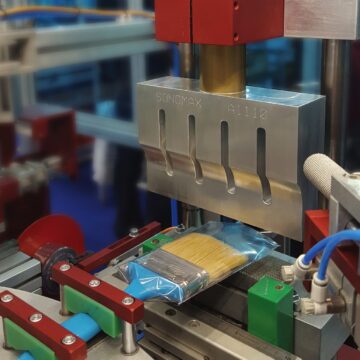

- Blister

- Zip closure

- Safety lock

- Tufted

- Packaging for fruit and vegetables

- Plasticised packaging for drinks and food

- Clean cutting of films without over-thickness

Advantages

- Fast cycle

- Regulatory compliance

- Perfect aesthetics

- Ease of cleaning

- Practicality

- Energy saving

- Safety and hygiene

- Guaranteed sealing

- Hermetic seal